The adaptability of die casting is one of the factors which have made it a success in Malaysia. The process allows manufacturers to make complex shapes using remarkable precision. This makes the process indispensable to industries that need elaborate shapes. In the automobile industry, for instance, die casting is used to produce lightweight yet robust parts that improve car performance as well as the efficiency of fuel. Similarly, in the electronic industry, this process is employed to build housings, heat-sinks as well as other crucial components. Die casting's versatility makes it a popular choice and makes it an integral component of Malaysia's manufacturing infrastructure. By offering cost-effective solutions without losing the quality of products, Malaysian companies have become the preferred suppliers of clients all over the globe.

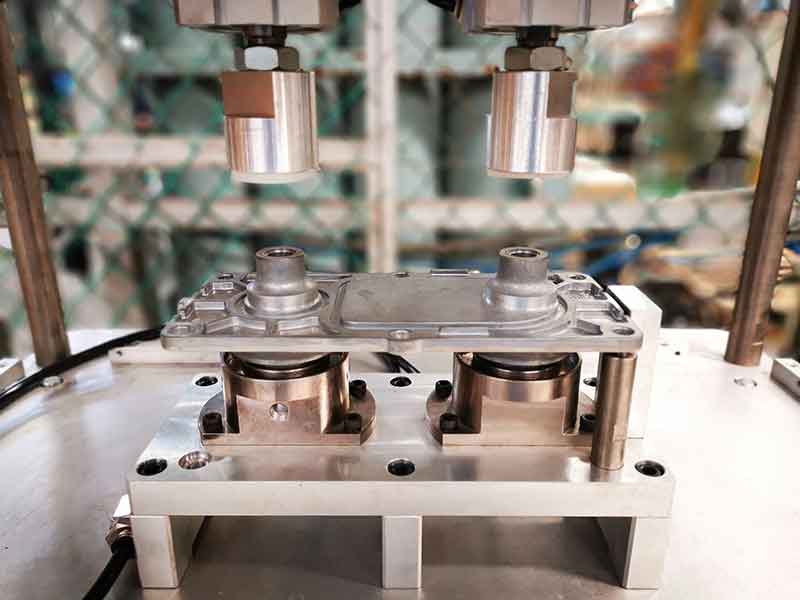

Innovation is the main driver of the industry of die casting in Malaysia manufacturing, with manufacturers continuously implement new technology to improve the efficiency of their operations. Automation has revolutionized die casting processes, using robotic equipment that guarantees precision and consistency in production. Innovative simulation tools are employed to improve design of molds, which helps in reducing material waste and improving product quality. A lot of Malaysian companies have also adopted Industry 4.0 practices, integrating IoT-enabled devices and information analytics in their processes. The advancements in technology not only increase efficiency, but they also allow producers to respond to the ever-changing demands of their clients. In keeping at the cutting edge of innovation, Malaysia's die casting industry is competitive on a an international scale.

Sustainability is now a major issue for companies that die cast in Malaysia which reflects a dedication to the environment. A lot of manufacturers are adopting environmentally friendly methods, like recycling metal scraps, and employing the most energy efficient machinery. The use of lightweight materials like aluminum and magnesium can also contribute to sustainable development, since these metals cut down on the amount of energy used in the final items they're used in, such as cars. Malaysian businesses are also experimenting with methods to reduce the carbon footprint of their production. the carbon footprint of their products. By prioritizing green manufacturing and a more sustainable approach to production, they are able to comply with global environmental standards and is able to meet the ever-growing demand for sustainable products. To acquire new details kindly check out Senadiecasting

The Malaysian government has been instrumental in supporting the growth of the die casting industry, providing incentives and creating collaborations between universities and industry. Research and development initiatives together with vocational education programs, guarantee a continuous pipeline of skilled talent for this industry. Export-oriented policies and the free trade agreement have helped Malaysia's standing as an international manufacturing hub. Through creating an environment for innovation and investment and ensuring that government assistance is continuing to propel the growth of the industry of die casting, ensuring its role in Malaysia's economic development remains substantial.

Die casting is an essential component of Malaysia's manufacturing landscape, driving innovation as well as economic growth and global competitiveness. Its versatility and precision make it indispensable for producing parts that comply with the strictest standards across various sectors. With a highly skilled workforce, modern infrastructure and a dedication to sustainable development the die casting industry in Malaysia is well positioned to face the future challenges and opportunities that lie in the coming years. With the demand for premium components that are precision engineered continues to grow, Malaysia will remain a important player in the manufacturing industry globally by delivering the most cutting-edge products and solutions to meet the evolving needs of industries across the globe.